|

A Guide to Implementing the Theory of

Constraints (TOC) |

|||||

|

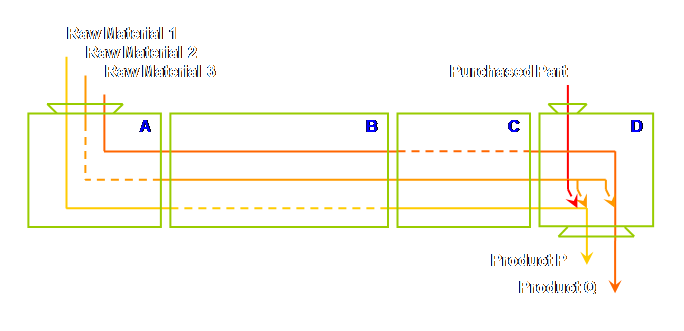

The P & Q Question Explained The P & Q is a simple process which makes just

two things; “P’s” and “Q’s.” The

objective of the exercise is to make a decision as to how to best maximize

the profit of this process. We can draw the flow of the process as follows.

We can make the process flow more explicit by

splitting out the flows for each product.

Let’s do that. For product P we have;

Let’s look at product Q. We have;

Because this is a perfect system we know exactly the

selling price and the actual demand, we also know the input prices. Let’s add these, keeping our chains

separate to keep things as simple as possible – remembering that the chains

share one physical process.

Let’s have a look.

Let’s reiterate; The selling price for P’s is $90 each and the market

demand (which is accurately known to the last unit) is 100 units per

week. The selling price for Q’s is

$100 each and the market demand is 50 units per week. In addition; The operating expense for the whole process is $6000

per week. In this ideal situation

resource availability is; 60 minutes per hour, 8 hours per day, 5 days per

week, or 2400 minutes per week. There

is never any waiting, when one step is finished; the next step is immediately

ready. Note however, there is no multitasking. Resource A, B, C, D can only do their

nominated jobs. In processes where you

might visualize the resources as people, then its not uncommon for managers

to assume, for the purposes of this exercise, that the resources can

multitask – even though in real-life they are happy for their own resources

to do the same job year in – year out. Let’s also

remind ourselves that; Profit =

throughput – operating expense, and Throughput =

selling price – material costs. Given this information, the question then is; how much profit can we generate per week from this process? Have a go at

this exercise and then, once you have an answer, any answer, return to the

measurements page. To return

to the previous page press Alt key + left arrow.

(1) Goldratt,

E. M. (1990) The

haystack syndrome: sifting information out of the data ocean. North River Press, pp 64-71. This Webpage Copyright © 2003-2009 by Dr K. J.

Youngman |